Diesel Particulate Filters

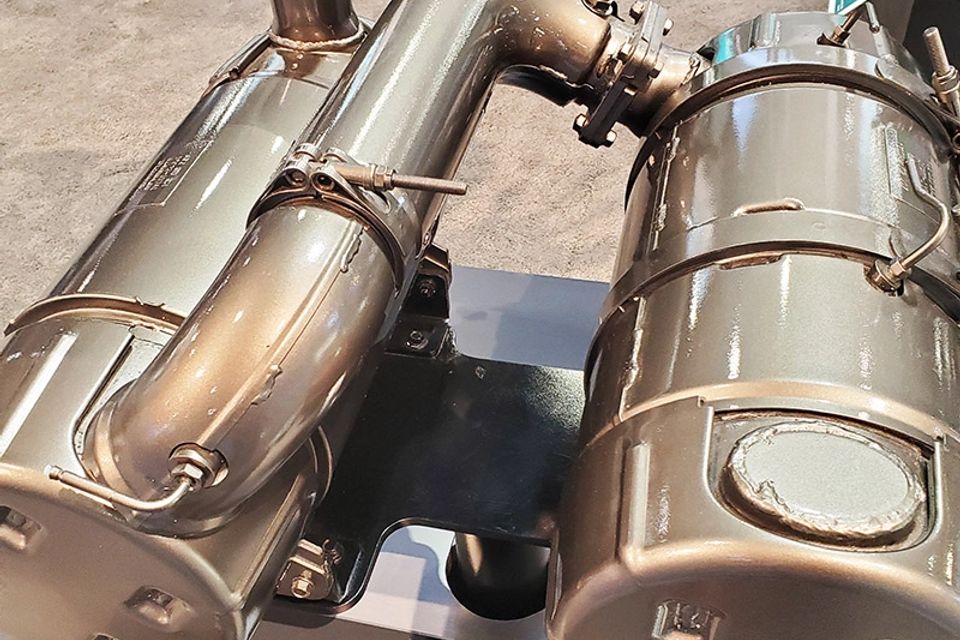

A diesel particulate filter, or DPF, is an essential component of the aftertreatment system in diesel-powered vehicles. Not only does it play a key role in reducing diesel engine emissions, but it can also help to improve engine performance. If you’re new to diesel-powered vehicles, you may wonder what a it does and why its important.

Different Types of DPFs

Several different types of filters are available, each with unique features and benefits. Two of the most common types include:

Ceramic

Of all the DPF options available, cellular ceramic honeycomb filters are the most commonly used. Ceramic filters, such as silicon carbide and cordierite, are known for their high thermal resistance, reliable durability and high filtration efficiency.

Metal Fiber

Metal fiber filters are made from a mixture of stainless steel and ceramic fibers. While metal DPFs are less common, they are more resistant to thermal shock and lighter in weight, which can help to improve fuel efficiency. These filters are often used in off-road vehicles and heavy-duty diesel engines.

- How Do They Work?

DPFs are designed to reduce harmful emissions by capturing and removing particulate matter (PM) emissions produced by the combustion process from diesel engine exhaust. Typically located in the exhaust system of a diesel vehicle, it traps these tiny, solid particles and retains them until they can be oxidized or burned within the filter itself through an oxidation process called regeneration. - Why Are They Important?

Diesel engines produce significant PM emissions, consisting of tiny particles of soot, ash, and other pollutants. These particles are so small that they can easily enter the lungs and bloodstream, causing various health problems such as respiratory issues, heart disease, and even cancer. Diesel particulate filters are crucial in reducing particulate matter emissions from diesel engines. By capturing these tiny particles before they are released into the air, DPFs help to improve air quality and reduce the carbon footprint of diesel engines.

DPFs can also help to extend the life of the engine and its components by reducing the wear and tear that soot particles can cause, resulting in better engine performance and fuel efficiency in the long run.

Different Types of DPFs

Several different types of filters are available, each with unique features and benefits. Two of the most common types include:

Ceramic

Of all the DPF options available, cellular ceramic honeycomb filters are the most commonly used. Ceramic filters, such as silicon carbide and cordierite, are known for their high thermal resistance, reliable durability and high filtration efficiency.

Metal Fiber

Metal fiber filters are made from a mixture of stainless steel and ceramic fibers. While metal DPFs are less common, they are more resistant to thermal shock and lighter in weight, which can help to improve fuel efficiency. These filters are often used in off-road vehicles and heavy-duty diesel engines.